About EMI Shielding Effectiveness

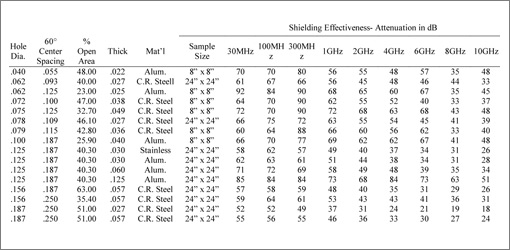

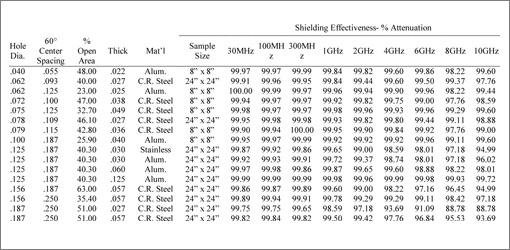

Perforated metal is used to enclose electrical devices to attenuate the EMI/RFI radiation they emit and to ventilate them at the same time. Many questions have been asked about which perforated patterns should be used to satisfy both of these design requirements and about the shielding effectiveness of various perforated patterns and materials. To answer these questions, the IPA contracted with Intertek Testing Services testing laboratories in Boxborough, Massachusetts to evaluate the shielding effectiveness of 16 perforation and material combinations at 9 frequency levels.*

The results of these tests with descriptions of the test samples and the frequencies tested are shown in the charts on this page. Results have been expressed in dB of shielding attenuation and in percent of attenuation. Details of the tests are available from the IPA.

The test results show that a shielding effectiveness of 40 dB provides 99 percent attenuation of the electromagnetic (EMI/RFI) radiation while a shielding effectiveness of 40 dB is the targeted minimum in most applications. Very effective shielding was provided by most samples up to frequencies of 7 GHz. Above that frequency, some of the samples dropped below 99 percent effective even at the highest frequency level of 10 GHz. The obvious conclusion to be reached is that there are many perforated patterns from which designers can choose to meet their design requirements.

The largest single source of leakage is along contact surfaces between two parts. If a tightly sealed electrical connection is not made, the leakage through the interface can be greater than through the structure.