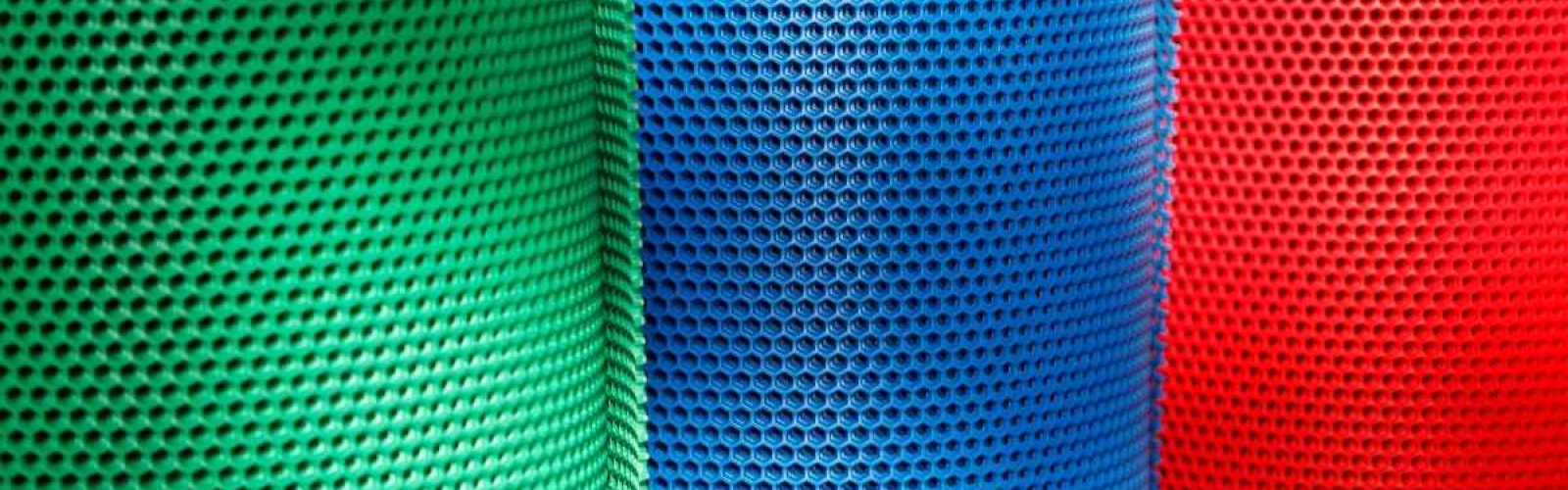

Some projects call for the strength of perforated metal — but not every environment or application can support heavy or heat-conductive materials. That's where perforated plastic shines. Lightweight, durable, and corrosion-resistant, perforated plastic sheets and panels deliver outstanding performance in industries where weight, cost, or environmental conditions matter most.

Accurate Perforating manufactures high-quality perforated plastic sheets and panels that combine functionality with design flexibility, helping you bring projects to life with confidence.

What Is Perforated Plastic?

Perforated plastic is created using a precision punching process that produces sheets in various thicknesses, hole sizes, and perforation styles. At first glance, a perforated plastic panel looks identical to a perforated metal panel — but with advantages that make it ideal for specific applications.

-

Lightweight: Easy to transport, handle, and install.

-

Chemical and corrosion resistance: Perfect for harsh environments where metal would rust or degrade.

-

Budget-friendly: A cost-effective solution for projects with tighter budgets.

-

Thermal stability: Unlike metal, plastic panels do not heat up in direct sunlight.

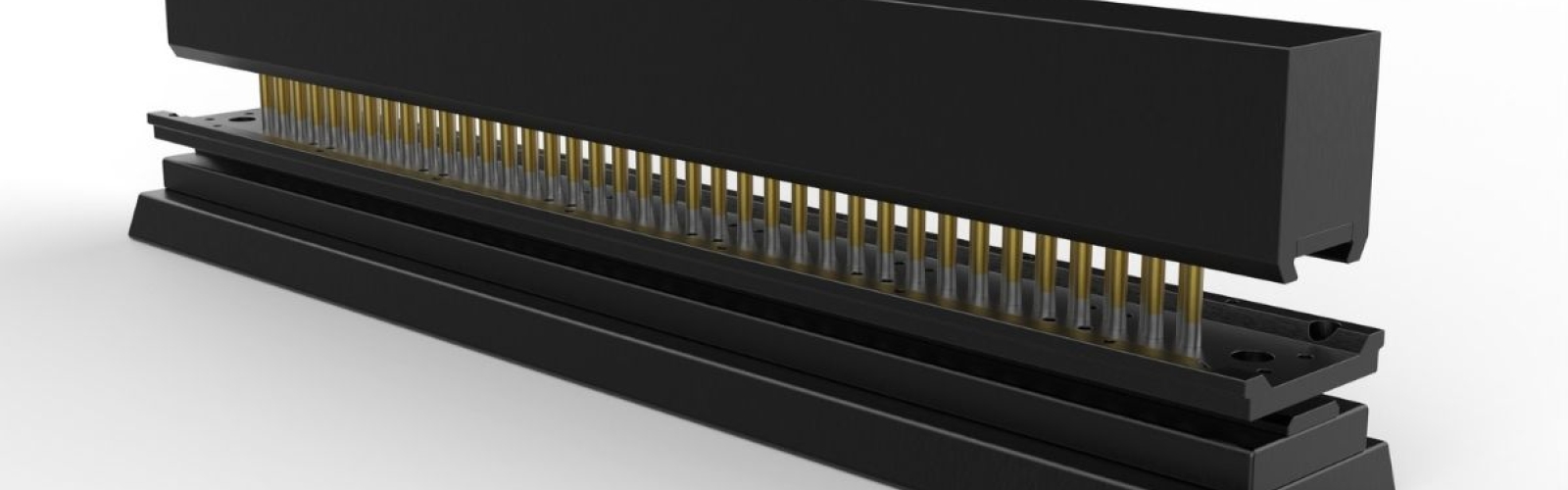

How Perforated Plastic Is Made

Perforated plastic is produced using a die-and-punch process, one of the most reliable and efficient methods for creating precise hole patterns. In this process, a punch (male tool) presses through the sheet into a die (female tool), mechanically shearing out the hole. The small punched-out pieces — often called chads or slugs — are removed, leaving behind a clean, uniform opening.

This method offers several advantages:

-

Speed: High throughput makes it ideal for medium- to high-volume production.

-

Consistency: Ensures uniform hole size and spacing across large sheets.

-

Flexibility: Works with plastics of varying thicknesses, enabling both commodity and custom designs.

-

Precision: Tight control over porosity makes it especially effective for filtration, airflow panels, and fluid distribution applications.

Because the process is scalable and cost-effective, die-and-punch perforation is widely used in industries such as automotive, construction, and industrial filtration. It's also adaptable to custom patterns, giving designers the freedom to specify unique hole shapes and layouts.

Benefits of Perforated Plastic

-

Easier installation with less structural strain.

-

Offers a lower cost compared to many perforated metal options.

-

Resistant to rust, corrosion, and chemical damage.

-

Energy efficiency by improving airflow and natural light diffusion.

-

It can be customized in a variety of thicknesses, shapes, and patterns.

Perforated Plastic Applications

Perforated plastic offers the same versatility as perforated metal, making it a wise choice for a number of applications:

-

Automotive: Speaker grilles, interior ventilation, and custom components.

-

Filtration & Ventilation: Airflow panels and filters for HVAC and industrial equipment.

-

Building Design: Perforated plastic sunshades and decorative façade elements that resist weathering.

-

OEM Components: Cost-effective inserts, enclosures, and packaging elements.

Design Options & Patterns

With a tooling library of more than 2,000 patterns, Accurate Perforating gives you nearly unlimited design flexibility. Choose from:

-

Shapes: round, square, slots, hexagons, cloverleaf, ornamental.

-

End styles: finished, unfinished, symmetrical, or asymmetrical.

-

Customization: unique hole sizes and spacing to meet your specifications.

Don't see what you need? Contact us about a custom tool to create a custom perforated plastic pattern tailored to your exact project.

Fabrication & Finishing Services

Accurate Perforating is more than a sheet supplier — we provide complete fabrication and finishing services, ensuring your perforated plastic is ready for installation.

-

Cutting, forming, shearing, and assembly

-

Robotic and manual welding, hardware insertion, and riveting

-

In-house powder coating with RAL and Pantone color matching

-

Decals, logos, silk-screening, and custom graphics

-

All perforated plastics are degreased and washed before shipment

Why Choose Accurate Perforating for Perforated Plastic?

With more than 80 years of perforating expertise, Accurate Perforating has the knowledge, equipment, and dedication to deliver results you can trust.

-

Chicago-based, serving customers nationwide.

-

Proven quality control, packaging, and warehousing.

-

An experienced team that is ready to consult on design, material choice, and performance needs.

-

Full service — from perforation through finishing and fulfillment.

Let's Talk About Your Project

Whether you’re designing a speaker grille, architectural sunshade, or industrial filter, Accurate Perforating can provide the right perforated plastic solution.

Request a quote today and let our team help you choose the perfect pattern, finish, and fabrication options for your next project.