Audio Applications

Custom speaker grills, manufactured from perforated metal panels, improve the appearance and performance of audio equipment. Perforated metal speaker grilles, for example, are top-rated options for customized sound systems. At Accurate Perforating Company, we specialize in manufacturing custom metal speaker grilles that are high quality and reliable.

Types of Speaker Grills

Speaker grilles come in various types, each with its advantages and disadvantages. Some of the more common types include:

- Mesh grilles: These are manufactured from a thin sheet of perforated metal or plastic with small holes punched in it. They are the most common type of grill that offers a good balance of protection and sound quality. However, they can diffract sound waves, affecting the sound of specific pieces.

- Waffle grilles: These grills have a series of raised squares or rectangles. They are more durable than metal mesh grilles and can help diffuse sound waves. However, they block more sound than typical perforation due to the manufacture of the raised type pattern.

- Foam grilles: Foam grills start with a soft, absorbent material. While they are superior at protecting speakers from dust and dirt, they tend to absorb sound waves, forcing the user to turn up the volume.

Before choosing a specific type of speaker, you'll need to ask what you are trying to do with the unit. This can help your product and engineering teams develop the right concept for your sound needs. Accurate Perforating can help you make the custom speaker grill of your dreams.

Benefits of a Perforated Speaker Grill

A quality perforated speaker grill can make all the difference regarding sound quality, product longevity, and branding. A metal mesh speaker grill has to be a triple performer — delivering acoustics, aesthetics, and durability. The speaker grill is carefully designed to allow appropriate sound while protecting the speaker components from the elements. At the same time, it provides a design that accurately represents the product.

Perforated metal is the best material to meet the unique requirements needed for intricate speaker grilles and screens. Accurate Perforating Company supplies standard and customized speaker mesh metal grills to manufacturers, designers, architects, and sound engineers.

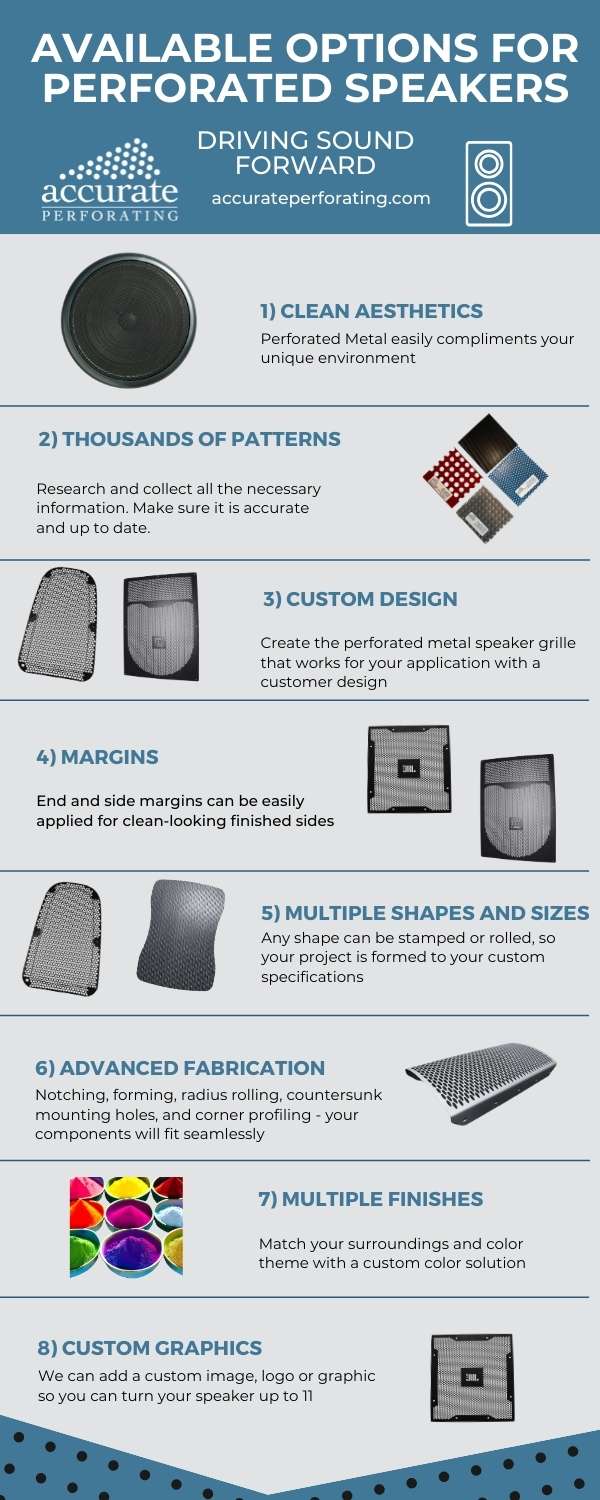

Available Options for Custom Speaker Grills

We work closely with you regarding custom speaker grill specifications to ensure you get what you need. Here are just a few options and considerations:

- Clean aesthetics that complement your unique environment

- Customize for your desired open area. Hole patterns and sizes are optimal for acoustic performance.

- Custom patterns to achieve the design you prefer

- End and side margins for clean-looking finished sides

- Choose any shape that can be stamped or rolled to form your project to your metal mesh sheet specifications.

- Notching, forming, radius rolling, countersunk mounting holes, and corner profiling so the component fits seamlessly into the speaker cabinet.

- A variety of finishes to match your color theme

- Custom image perforating to brand your speaker with your company name or logo

We help you with branding by providing perforating options to replicate logos or design motifs in the metal pattern. We can also apply your logo as a decal or sticker, plastic card, or electronic device with your brand onto the speaker grill mesh sheet.

Why Choose Accurate Perforating?

Accurate Perforating Company simplifies your purchase of perforated metal audio components by taking a customer-centric approach. Custom speaker grilles require high open area patterns. We work with audio engineers to create designs that meet exacting criteria, are durable in many demanding outdoor applications, and are pleasing to the eye.

There is no need to buy inexpensive parts from one distributor and then send them to another manufacturer for the proper perforated speaker grill assembly and finishing.

- We have the expertise and equipment to design, perforate, punch, roll, and finish audio components.

- All work is done in-house, in one place, and correctly — which removes headaches and worry.

- Everything will integrate seamlessly in assembly, and the component's edges match up for a clean, finished look.

- We also can work with your other suppliers on a project — we have an excellent track record for collaboration.

Whatever the process, your result is a perforated metal speaker that's a top performer.