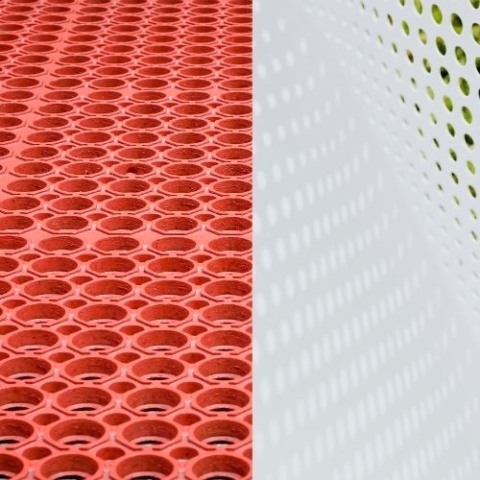

When most people think of perforated materials, metal comes to mind first. That makes sense — perforated metal is durable, versatile, and used across countless industries. But there are times when metal isn't the best solution. That's where perforated plastic applications provide a more innovative alternative.

Why Consider Perforated Plastic?

Perforated plastic sheets look and function a lot like their metal counterparts, but they bring a different set of strengths to the table:

-

Lightweight performance — easier to handle, transport, and install, especially for overhead or mobile systems.

-

Corrosion resistance — ideal for harsh or chemical-heavy environments where metal would rust or degrade.

-

Budget-friendly — a cost-effective alternative for projects that don't require the full strength of steel or aluminum.

-

Temperature control — plastic doesn't heat up under sunlight the way metal does, making it helpful in building or cooling applications.

These advantages make plastic the material of choice for specific industries and design challenges.

Common Perforated Plastic Applications

While perforated metal dominates in structural and heavy-duty projects, perforated plastic excels in several niches. Here are some of the most common and effective perforated plastic applications:

-

Ventilation & airflow — plastic panels allow circulation in enclosures, walls, or equipment housings while staying cool to the touch and resisting corrosion.

-

Automotive components — widely used in speaker grilles, ventilation covers, and lightweight trim pieces, where reducing weight and cost is essential.

-

Lighting diffusers — perforated plastic helps soften and distribute light evenly in architectural, retail, and industrial settings without adding unnecessary weight.

-

Filtration systems — in water treatment, food processing, or lab equipment, perforated plastic holds filter media in place while resisting moisture and chemical exposure.

-

Agricultural equipment — used in seed sifters, greenhouse ventilation panels, and lightweight machinery guards where corrosion resistance is critical.

-

Consumer products — everything from storage bins and baskets to protective casings for electronics can integrate perforated plastic for airflow and aesthetics.

-

Cost-sensitive builds — projects that require perforated performance without the expense of metal, such as temporary structures or non-load-bearing partitions.

Perforated Plastic vs. Perforated Metal

The choice isn’t about which is “better,” but which is right for the job. Metal remains unmatched for load-bearing strength, longevity, and fire resistance. Plastics, on the other hand, excel in areas where weight reduction, corrosion resistance, or cost control are top priorities.

In fact, many customers use both — perforated metal in high-stress areas and perforated plastic where flexibility and lighter weight are key.

Partner with a Trusted Supplier

At Accurate Perforating, we’ve spent more than 80 years helping customers find the right material for their needs. Whether it’s carbon steel, aluminum, stainless steel, or perforated plastic, our team can guide you through the trade-offs and help you make the right call for your project.