Perforated stainless steel is one of the most versatile materials we work with. Its strength, corrosion resistance, clean appearance, and long-term performance make it a reliable choice across architectural, industrial, agricultural, and medical applications.

At Accurate Perforating, we combine precision perforating with deep material knowledge to help customers select the right stainless steel grade, pattern, and thickness for both form and function. Whether the goal is airflow, sound control, screening, or visual impact, stainless steel delivers consistent results.

What Is Perforated Stainless Steel?

Perforated stainless steel is produced by punching controlled hole patterns into flat stainless steel sheets. The result is a material that balances strength, open area, and durability—without sacrificing corrosion resistance.

Because stainless steel maintains its structural integrity even after perforation, it's widely used in a range of applications, including baking trays.

Types of Patterns

Stainless steel perforated metal can be manufactured with a wide range of hole sizes, shapes, and layouts. Pattern selection depends on performance requirements, aesthetics, and open area.

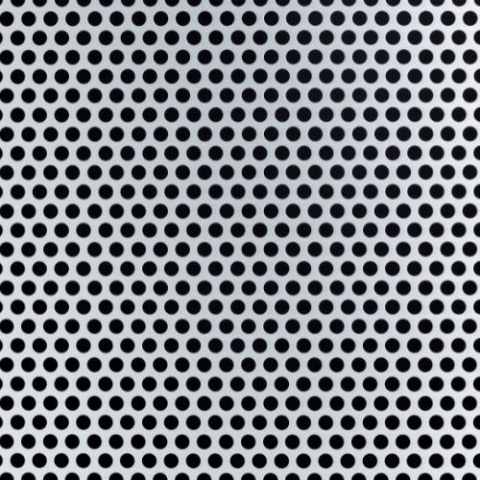

Round Hole

The most commonly specified pattern. Available in straight or staggered layouts, round holes provide excellent strength-to-open-area balance—up to approximately 65% open area. Typical uses include ventilation panels, noise control, filtration, and airflow management.

Square Hole

Square perforations create a more linear, contemporary appearance and provide larger open areas than comparable round holes.

Slotted Hole

Elongated holes arranged in straight or staggered rows allow directional airflow, drainage, or the passage of materials. We see these being used in machine guards, speaker grilles, and automotive components.

Decorative Patterns

Custom patterns are designed primarily for visual impact while maintaining performance.

Typical uses: façades, screens, architectural accents, interior panels.

Hexagonal (Hex) Patterns

A staggered hex layout offers an excellent strength-to-weight ratio with a distinctive visual rhythm.

Stainless Steel Grades We Perforate

Selecting the correct grade is essential for performance, durability, and cost control. Some of the grades of stainless steel we commonly perforate include:

- 303 Stainless Steel – Machinable grade with lower corrosion resistance; used in shafts and specialty components.

- 304 Stainless Steel – The most versatile option, offering strong corrosion and heat resistance for general-purpose applications.

- 304L Stainless Steel – Low-carbon version of 304 for welded or corrosion-sensitive environments.

- 316 Stainless Steel – Superior corrosion resistance for marine, chemical, or coastal applications.

- 316L Stainless Steel – Stabilized for extreme corrosive conditions and higher temperature ranges.

- 410 Stainless Steel – Higher strength with moderate corrosion resistance for mechanical components.

- 430 Stainless Steel – Cost-effective option for less demanding environments.

Benefits of Stainless Steel Perforated Metal

Durability

The punched holes do not compromise stainless steel's strength or resistance to corrosion, wear, and heat—making it ideal for long-term use indoors or outdoors.

Versatility

From filtration and airflow to screening and architectural design, stainless steel adapts to both functional and decorative applications.

Sound Control

Perforated stainless steel panels help disperse and absorb sound, especially when paired with acoustic backing materials.

Aesthetic Appeal

Clean lines and modern finishes make stainless steel a popular choice for contemporary architectural designs.

Ventilation & Airflow

Perforated panels allow controlled airflow and light transmission, contributing to energy efficiency and occupant comfort.

Sustainability

Stainless steel is 100% recyclable, supporting environmentally responsible building and manufacturing practices.

Partner With Accurate Perforating

Stainless steel perforated metal performs best when it's engineered correctly from the start. At Accurate Perforating, we combine decades of experience, advanced equipment, and collaborative project support to deliver solutions that last. From 24 gauge to 1/4" thickness, sheet widths up to 60", and thousands of custom patterns, we manufacture stainless steel perforated metal tailored to your application—on time and to spec. Let's talk about your project. Our team is ready to help you select the right material, pattern, and finish for long-term success.

Reference: https://www.iqsdirectory.com/articles/perforated-metal/perforated-stainless-steel.html